- 사업분야

- 대기오염방지시설

대기오염방지시설

- 1. 입자상 물질(DUST) 처리설비

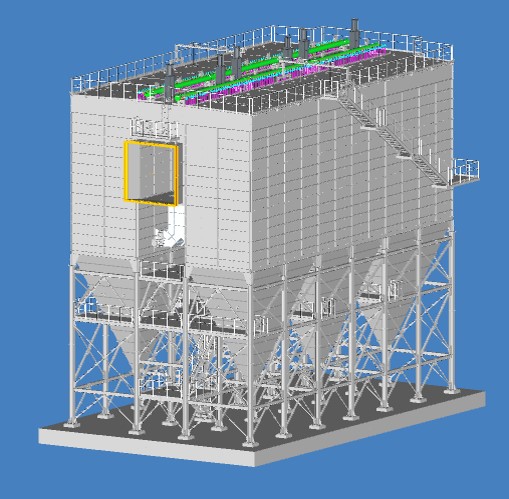

- BAG FILTER (여과식 집진설비)

- CYCLONE (원심력 집진설비)

- 2. 가스상 물질(악취) 제거설비

- SCRUBBER (습식 세정탑)

- A/C TOWER (활성탄 흡착 설비)

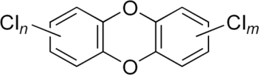

- 다이옥신 저감설비 (활성탄 투입 설비)

- 3. 적용 공정

- 소각장, 등 산업계 전 공정에 적용

- 제철,제강 / 제지 / 화학

- 시멘트 / 비철금속

- 발전소

- 1. FGD(Flue Gas Desulfurization)

- 습식 탈황 (WET FGD)

- 반건식 탈황 (Semi-Dry FGD )

- 건식 탈황 (DRY FGD)

- 2. 탈질설비 (De-Nox) System

- SNCR (Selective Non Catalytic Reduction)

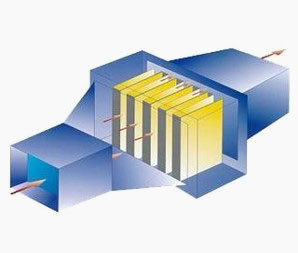

- SCR (Selective Catalytic Reduction)

- 3. 적용 공정

- 대형 : 석탄화력발전소

- 중.소형 : 소각장, 석유화학

- 5,6차 전력수급계획에 반영된 국내 발전소

- 해외 200MW급 이하 석탄화력 발전소 증가 추세

Incineration & Flue Gas Treatment System

DeNOx system/Dioxin Destruction System (SDS/SDDS)

| Typical Applications |

|

|---|---|

| Advantages |

|

| Chemistry |

|

SDS/SDDS: System/Catalyst/Performance

| System: Lateral Flow Reactor |

|

|

|---|---|---|

| Catalyst CRI S-090 |

|

|

| Performance |

|

|

주요 실적

Industrial Waste Incinerator – HANSOL Paper, Daejeon

- BFBC(SNCR) – WHB - PAC – Dry Lime Injection – BH - SCR

- Start-up: 2019.12

- Flow Rate : 135,000 Nm3/h

- Catalyst : Honeycomb Type (CERAM , Austria)

- Temperature : 165°C and 200°C

- Pressure drop(SCR) : < 6 mbar (actual 5)

- SOx: < 5 ppm (actual 0.5)

- Inlet NOx: < 75 ppm and < 160 ppm

- Outlet NOx: < 15 ppm (actual 2)

- Outlet NH3: < 15 ppm (actual 0)

| 항목 | 투자전 | 성능시험 결과 | 개선 효과 |

|---|---|---|---|

| NOx Outlet 농도(ppm, 12%) | 52 | < 15 | 70% 개선 |

| 약품 소모량 (UEEA 40%, Ton/Day) | 7 ~ 8 | < 3 ~ 4 | 50% 감소 |

| NH3 Slip (ppm, 12%) | 19 | < 5 | 80% 감소 |

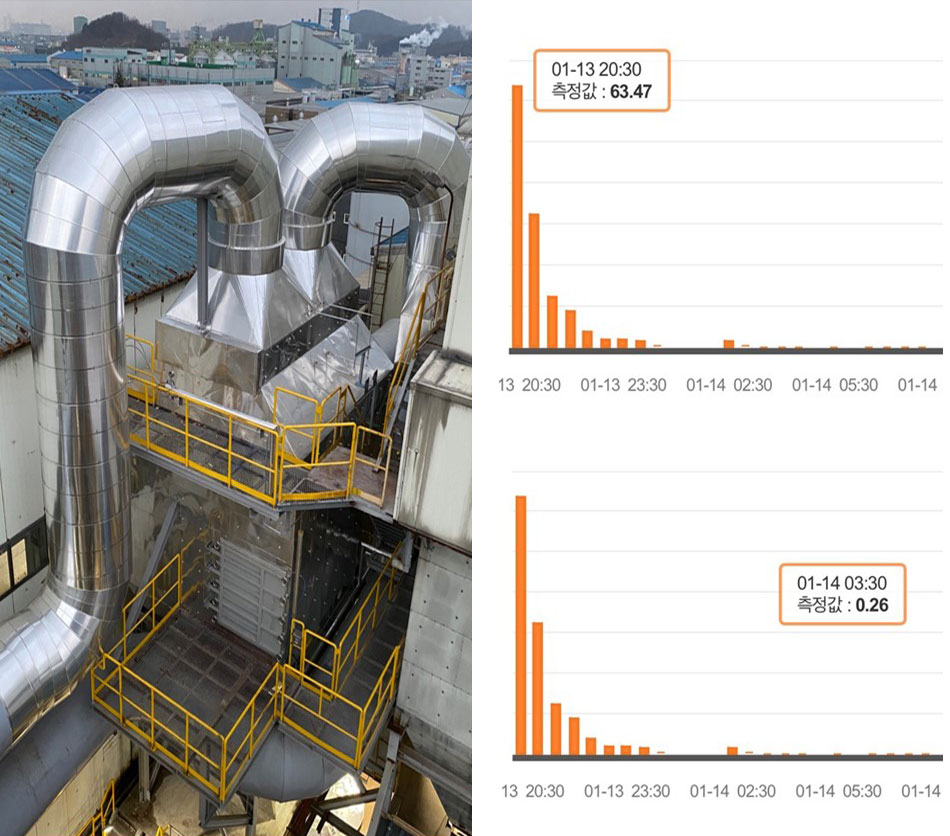

Industrial Waste Incinerator – DAEHAN Paper, Osong

- BFBC(SNCR) – WHB - PAC – Dry Lime Injection –(BH+Catalyst 일체형)

- Startup: 2020.12

- Flow: 90,000 and 120,000 Nm3/h

- Catalyst : Shell S-090 2.5 Panel Type

- Pulsing Method : Hybrid Jet Injector

- Temperature : 170°C and 200°C

- Pressure drop(BH + Catalyst) : < 21 mbar (actual 14)

- SOx: < 5 ppm (actual 1.5)

- Inlet NOx: < 70 ppm and < 200 ppm

- Outlet NOx: < 20 ppm (actual 6)

- Outlet NH3: < 15 ppm (actual 5)

- Outlet Dioxin: < 0.05 ngTEQ/Nm3

| 항목 | 시공 전 | 성능시험 결과 | 개선 효과 |

|---|---|---|---|

| Flow Rate (Nm3/hr) | 90,612 | 105,000 | 16% 증가 |

| 약품 소모량 (탄산암모늄9%, kg/hr) | 527 | 330 | 37% 감소 |

| Pressure Drop(BH+SCR, mmAq) | 250~300 | 140 | 44% 감소 |

| I.D Fan Motor 부하율(정격전류, %) | 95 | 82 | 14% 감소 |

Industrial Waste Incinerator – TAELIM Paper, Ansan

- Grate(SNCR) – WHB - PAC – Bicarbonate - SDR – BH – SCR - Scrubber

- Startup: 2021.01

- Flow: 80,000 and 100,000 Nm3/h

- Catalyst : Shell S-090 2.5 Module Type

- Pulsing Method : Hybrid Jet Injector

- Temperature : 160°C and 200°C

- Pressure drop(Only SCR) : < 4 mbar (actual 2)

- SOx: < 5 ppm (actual 1.5)

- Inlet NOx: < 70 ppm and < 200 ppm

- Outlet NOx: < 10 ppm (actual 1)

- Outlet NH3: < 15 ppm (actual 5)

- Outlet Dioxin: < 0.08 ngTEQ/Nm3

+ O2 => CO2 + HCl

+ O2 => CO2 + HCl